Algeria spurs on local auto manufacturing

Traditionally a net importer of vehicles, Algeria is strengthening its bid to become a regional auto-manufacturing hub by attracting major industry players to its shores.

Three recent agreements should see French manufacturer Peugeot-Citroën, Italy’s Iveco and Germany’s Volkswagen roll out new assembly factories in the country over the next two years.

Encouraging investment in domestic production capacity forms part of a broader bid by the government to curb import spending and re-industrialise Algeria’s economy, with a sharp focus on increasing local content.

Major expansion drive

Algeria’s automobile industry is generating significant interest among investors who see it as an attractive alternative to help offset stagnant sales in Europe. The Algerian auto market – the second largest in Africa – has experienced strong growth over the last five years, which is expected to continue through to 2020.

The government is keen to capitalise on Algeria’s competitive labour costs and strategic location on the northern coast of Africa, which offers European manufacturers the opportunity to extend their reach into Africa, where car ownership averages around 130 vehicles per 1000 inhabitants, according to industry media, roughly one-fourth the rate in Europe.

Peugeot-Citroën’s plans for expansion will see the French giant build a plant in the north-western region of Oran, where fellow French car brand Renault opened Algeria’s first auto-production factory in November 2014.

Production at Peugeot-Citroën’s new facility will focus largely on the Citroën C-Elysee, the Peugeot 301 and the Peugeot 208 models.

Renault’s €50m plant, the product of a deal sealed by the firm with Algeria’s National Society of Industrial Vehicles and National Investment Fund, has produced more than 20,000 vehicles to date.

The French manufacturer has since expanded its operations at the facility to meet a yearly production target of 25,000 vehicles. Renault expects to add a third eight-hour shift at the factory to boost annual production to 75,000 units by 2019.

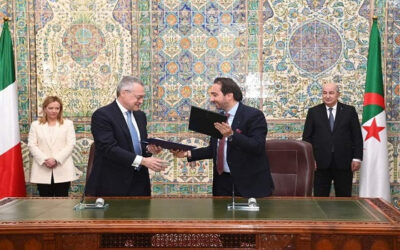

Iveco, meanwhile, plans to build a truck assembly plant in an industrial zone south-east of the capital Algiers, in Bouïra, which is expected to be operational by November 2016, Pierre Lahutte, president of Iveco, told media in December.

Being developed at a total estimated cost of €35m, the facility will have an initial production capacity of 1500 vehicles per year, scalable up to 8000 by 2024.

Under a third deal, Volkswagen is set to open a €170m plant in the north-western city of Relizane, which will assemble up to 100,000 vehicles per year.

Further agreements could be in the pipeline, according to Abdesalam Bouchouareb, minister of industry and mines.

“We are also in talks with an Iranian partner, and Nissan has expressed a desire to set up in Algeria,” he told media in January, adding that discussions with Fiat and Hyundai were also advancing.

Targeting value chains

While Algeria has made progress in expanding domestic assembly, other segments, including the manufacturing of tyres and auto parts, are developing at a somewhat slower pace, reflecting a broader challenge facing Algerian industries.

“It is important for the level of industrial activity to be sufficient enough to create demand for subcontractors’ services,” Guillaume Josselin, managing director of Renault Algeria, told OBG late last year. “That is why large industrial projects are of key importance; they create demand, which allows for increased local integration into the value chain.”

While local value chain development is set to receive a boost from the government’s plans to create close to 50 industrial zones across the country, there is also evidence of early progress on this front in the automobile industry.

In early 2016 Mercedes announced plans to establish a spare parts manufacturing centre in the south of the country, while Renault is currently conducting feasibility studies to construct a spare parts manufacturing facility in Constantine in north-east Algeria.

Renault Algeria is working to raise its local content rate from 16% to 42% by 2019 through subcontracting of parts like upholstery, wiring and window grates. In late 2015 the company sealed deals with three local subcontractors for the procurement of plastic injection parts, cables and seats.

Similar efforts to increase local procurement and subcontracting in automotive industrial supply chains have yielded impressive results in neighbouring Morocco and Tunisia, both of which boast a large market of local automotive component manufacturers.

Import rationale

In the past, limited domestic auto manufacturing had forced Algeria to depend largely on automobile imports to meet domestic demand. The country imported around 300,000 vehicles in 2015 and close to 440,000 the previous year.

In a bid to stimulate local production, the government introduced import licence restrictions on automobiles, which came into effect this January. The government has set a 152,000-unit quota for a variety imported vehicles – both passenger and transport – for 2016, equivalent to just over half the units imported last year.

The new licensing regulations are already having a strong impact on the industry. According to data from the National Centre for Customs Statistics, auto imports were down by more than 66% year-on-year in January at 9309 units.

Categories

Recent Posts

- Ambassador MEHILA Messaoud, presents Mrs. Lyubka ALEXANDROVA with a selection of photographs

- The Embassy of Algeria in Sofia awarded for its Cultural Activities

- Mr Attaf, Equatoguinean counterpart hold talks

- Mr Attaf holds talks with CEO of AUDA-NEPAD

- The Minister Attaf, President of PAP holds talks